Die casting is a manufacturing process that has gained significant traction in Malaysia in recent years. With its ability to produce complex shapes with high precision and repeatability, die casting has become an integral part of the country’s industrial landscape. In this article, we will explore the die casting industry in Malaysia, its growth trajectory, key players, applications, challenges, and prospects.

The die casting industry in Malaysia has experienced steady growth, fueled by advancements in technology, increasing demand for lightweight and durable components, and the country’s strategic location within the Southeast Asian region. Companies in Malaysia specialize in both aluminum and zinc die casting, catering to a diverse range of industries such as automotive, electronics, aerospace, and consumer goods.

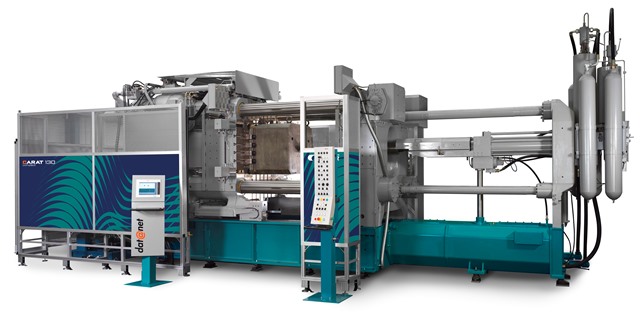

One of the primary reasons for the growth of die casting company Malaysia is the country’s skilled workforce and robust infrastructure. Malaysian die casting companies leverage state-of-the-art machinery, automation, and quality control processes to ensure the production of high-quality components that meet international standards. Additionally, the availability of raw materials and competitive labor costs further contribute to the industry’s competitiveness on a global scale.

In terms of applications, die casting finds extensive use in various industries due to its versatility and cost-effectiveness. In the automotive sector, die-cast components are utilized in engine parts, transmission housings, and structural components to reduce weight and improve fuel efficiency. Similarly, in the electronics industry, die-cast enclosures and heat sinks play a crucial role in dissipating heat and protecting sensitive electronic components.

Despite its growth and success, the die casting industry in Malaysia faces certain challenges. One such challenge is the increasing pressure to adopt sustainable and environmentally friendly practices. As the global focus on sustainability grows, die casting companies in Malaysia are exploring ways to minimize energy consumption, reduce waste generation, and implement recycling initiatives to mitigate their environmental impact.

Looking ahead, the future of die casting in Malaysia appears promising. With the ongoing digital transformation and Industry 4.0 initiatives, die casting companies are embracing automation, data analytics, and predictive maintenance to enhance efficiency, productivity, and quality. Furthermore, the growing trend towards light-weighting and the shift towards electric vehicles are expected to drive demand for die-cast components in the automotive sector.